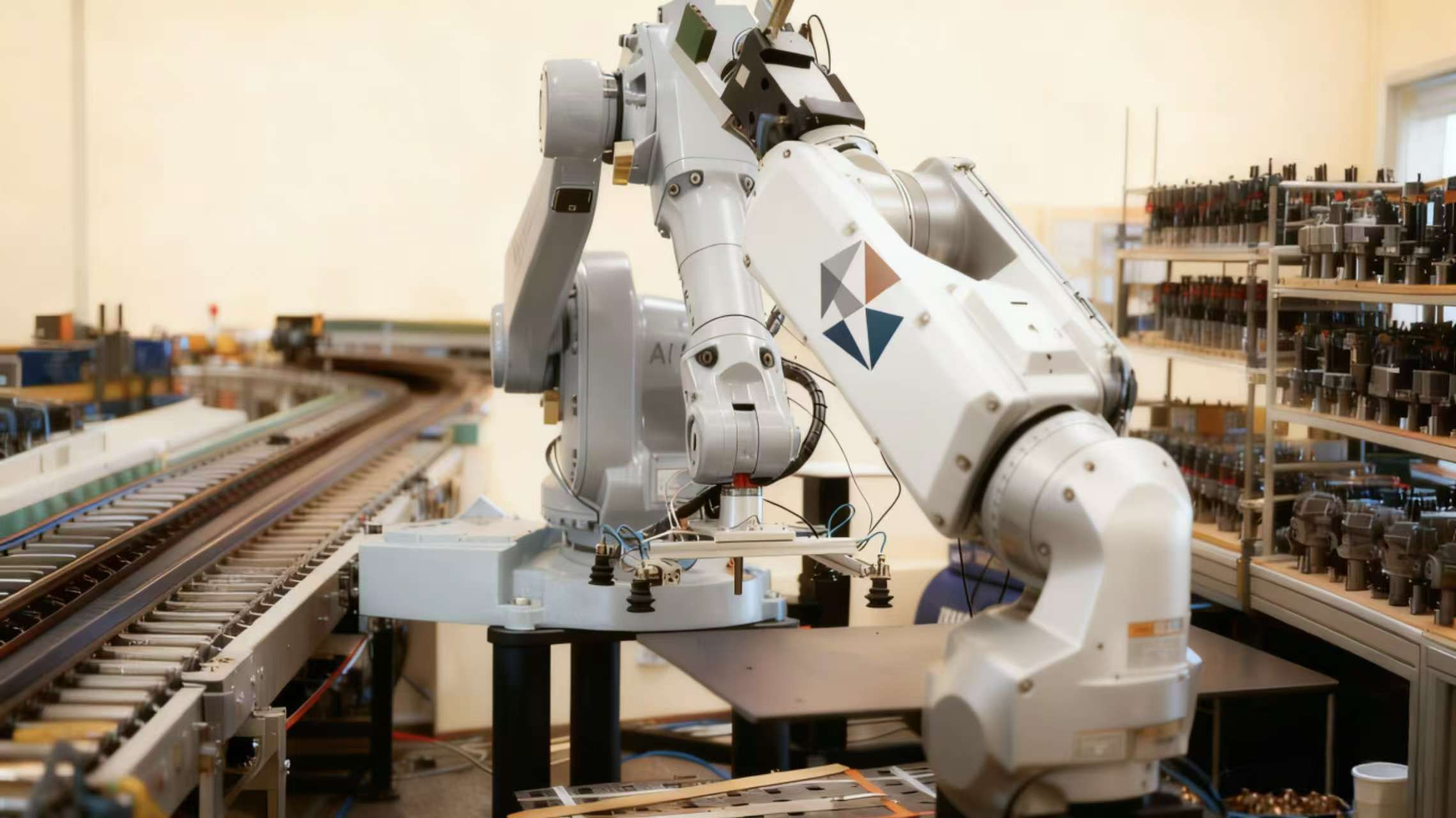

Robots have become indispensable in global manufacturing, working both collaboratively alongside humans and autonomously in precision-driven tasks. Modern industrial robots operate within complex three-dimensional work envelopes, executing repetitive motions with consistent accuracy—even in demanding environments.

The dynamic movement of robotic arms—characterized by rapid acceleration, multi-directional bending, torsion, and continuous flexing—places exceptional demands on cables. These cables must not only withstand intense mechanical stress but also be designed for compact, space-efficient routing to maximize the robot's range of motion and operational freedom.

Anyang® provides a comprehensive range of single- and multi-conductor cables tailored to robotic applications, including:

Our ANYANG® series delivers purpose-built, torsion-resistant cables for control, data, power, and sensing signals. These cables are engineered to endure the combined stresses of 3D movement, including:

From standard cables to application-specific assemblies, Anyang® supports robotic integration with reliable, high-performance connectivity—helping your systems move with precision, cycle after cycle.